Have you ever wondered what makes some tires last longer and perform better on the road? The secret often lies in how they are built.

One key method is called radial ply construction. Understanding this can help you make smarter choices when buying tires, ensuring your safety and saving you money. You’ll discover exactly what radial ply construction is, why it matters, and how it affects your driving experience.

Keep reading to learn how this simple design can make a big difference for you and your vehicle.

Credit: medium.com

Radial Ply Construction Basics

Radial ply construction is a type of tire design. It uses layers of fabric cords placed at 90 degrees to the tire’s centerline.

This design improves tire strength and flexibility. It also helps with better road contact and longer tire life.

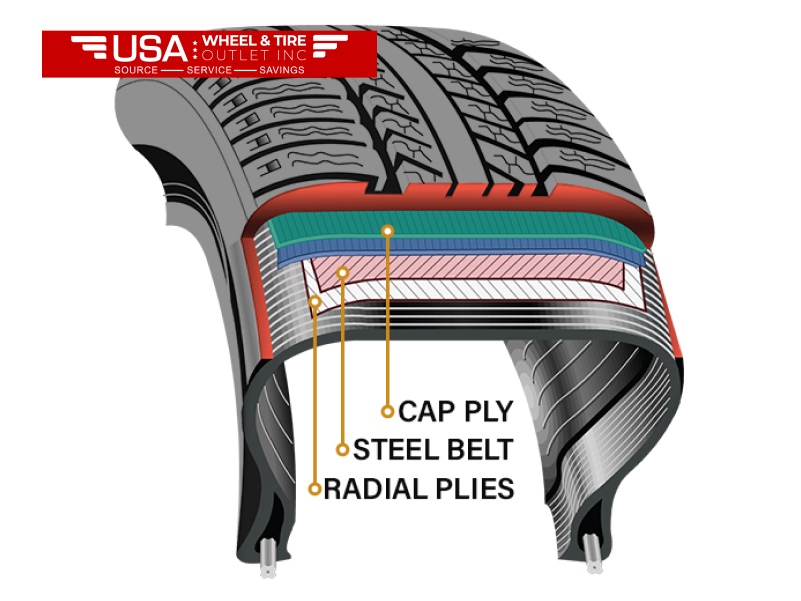

Core Design Features

Radial tires have cords that run straight across the tread from side to side. These cords are called plies.

The plies are placed at a 90-degree angle to the tire’s direction. Steel belts or fabric layers go under the tread to add strength.

- Plies run radially from bead to bead

- Steel belts support the tread area

- Flexible sidewalls allow better shock absorption

- Improved contact with the road surface

Materials Used

Radial tires use strong materials for durability and safety. Steel cords are common in the belt area.

Fabric cords, like polyester or nylon, form the plies. Rubber compounds cover the tire for grip and protection.

- Steel belts under the tread for strength

- Polyester, nylon, or rayon cords in the plies

- Rubber compounds for tread and sidewall

- Additional layers for heat resistance

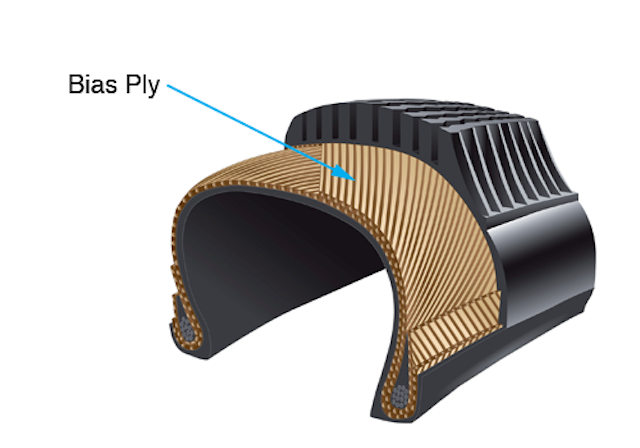

How It Differs From Bias Ply

Bias ply tires have cords placed diagonally across each other. This makes the tire stiffer but less flexible.

Radial ply tires have cords running at right angles. This gives better road contact and improves ride comfort.

| Feature | Radial Ply | Bias Ply |

|---|---|---|

| Cord Angle | 90 degrees to centerline | Diagonal, usually 30-40 degrees |

| Sidewall | Flexible | Stiff |

| Tread Support | Steel belts | Multiple fabric plies |

| Ride Comfort | Higher | Lower |

| Tire Life | Longer | Shorter |

Credit: en.wikipedia.org

Benefits Of Radial Ply Tires

Radial ply tires have layers of fabric running radially across the tire. This design helps the tire flex more and stay strong. Many vehicles use radial tires for better performance.

These tires offer several benefits that improve driving safety and comfort. Understanding these can help you choose the right tires for your vehicle.

Improved Traction And Grip

Radial ply tires provide better contact with the road surface. Their flexible sidewalls help keep the tire flat on the ground. This leads to improved traction and grip.

Better traction means safer driving in wet or slippery conditions. It helps your vehicle stop quickly and handle turns smoothly.

Enhanced Durability

The radial construction reduces heat buildup inside the tire. Heat is a common cause of tire wear and damage. This means radial tires last longer than other types.

Strong sidewalls and tread layers resist cuts and punctures better. This durability saves money on tire replacements.

Better Fuel Efficiency

Radial tires have lower rolling resistance. This means less energy is needed to keep the tire moving. Your vehicle uses less fuel as a result.

Using radial tires can reduce fuel costs and lower carbon emissions. This makes them a practical choice for daily driving.

Smoother Ride Experience

The flexible sidewalls of radial tires absorb road bumps better. This reduces vibrations felt inside the vehicle. You get a more comfortable ride on rough roads.

Less road noise also improves driving comfort. This is especially useful on long trips or city drives.

Applications Of Radial Ply Tires

Radial ply tires have many uses across different vehicle types. Their design gives better performance and longer life.

This article covers how radial ply tires fit passenger vehicles, commercial trucks, motorcycles, and specialty vehicles.

Passenger Vehicles

Passenger cars use radial ply tires for smoother rides and better fuel economy. These tires provide good grip in wet and dry conditions.

Commercial Trucks

Commercial trucks rely on radial ply tires for heavy loads and long distances. Their strong sidewalls help carry weight safely.

- Better durability on highways

- Improved fuel efficiency

- Longer tread life reduces replacements

- Enhanced stability under heavy loads

Motorcycles

Motorcycles use radial ply tires to improve handling and cornering. The flexible construction offers more contact with the road.

Specialty Vehicles

| Vehicle Type | Use of Radial Ply Tires | Benefits |

| Agricultural Machines | Field work and transport | Better traction and durability |

| Construction Vehicles | Heavy lifting and rough terrain | Improved load support and wear resistance |

| Military Vehicles | Off-road and tactical use | Enhanced toughness and stability |

Credit: usawheelstires.com

Manufacturing Process

The radial ply construction process builds strong tires by layering materials carefully. It uses special techniques to arrange cords in a specific way. This process improves tire strength and flexibility.

Each step in manufacturing is important. It ensures the tire performs well and lasts long under different conditions. Let’s explore the key parts of this process.

Layering Techniques

Radial tires use layers of fabric cords placed at a 90-degree angle to the tire’s centerline. These cords run from bead to bead across the tire. This design helps the tire flex without losing strength.

- The first layer is the body ply, made from textile or steel cords.

- Next, belts made of steel or other strong materials wrap around the ply.

- These belts add strength and help resist punctures.

- Finally, rubber layers cover the cords to protect them from damage.

Vulcanization

Vulcanization is a heating process that bonds rubber and fabric layers. It uses heat and pressure to make the tire strong and elastic. This step shapes the tire and cures the rubber.

| Vulcanization Stage | Description |

| Preparation | Assemble tire layers on a mold |

| Heating | Apply heat to activate chemical reactions |

| Pressurizing | Apply pressure to shape and bond layers |

| Cooling | Allow the tire to cool and harden |

Quality Control Measures

Manufacturers check every tire for defects before release. They test for durability, balance, and uniformity. Inspections catch issues early to ensure safety and performance.

- Visual inspections for surface flaws

- Uniformity tests to measure balance

- Strength tests under pressure

- Final checks using machines and sensors

Maintenance Tips For Radial Ply Tires

Radial ply tires offer better ride comfort and fuel efficiency. Proper care helps them last longer.

Follow simple maintenance steps to keep your tires safe and reliable on the road.

Proper Inflation

Keep your radial ply tires inflated to the recommended pressure. Check the pressure at least once a month.

Underinflated tires wear unevenly and reduce fuel economy. Overinflated tires can cause a harsh ride and uneven tread wear.

Regular Inspections

Look for cuts, cracks, or bulges on the tire surface. Also check for objects stuck in the tread.

- Inspect tires before long trips

- Check tread depth regularly

- Replace tires if you see damage or uneven wear

Tire Rotation

Rotate your tires every 5,000 to 8,000 miles. This helps tires wear evenly and extends their life.

Follow the rotation pattern recommended by your vehicle manufacturer or tire maker.

Balancing And Alignment

| Service | Purpose | Frequency |

|---|---|---|

| Balancing | Prevents vibration and uneven wear | Every 6,000 miles or when vibration occurs |

| Alignment | Keeps tires straight for even tread wear | Check annually or if steering pulls |

Keep your wheels balanced and aligned. This improves tire life and driving safety.

Future Trends In Tire Technology

Tire technology is evolving fast. Radial ply construction is key to this change. It impacts how tires perform and last. New trends focus on making tires better for the environment and smarter for users.

Understanding these trends helps us see the future of driving. It also highlights how tires can improve safety and efficiency on the road.

Eco-friendly Materials

Eco-friendly materials are changing how tires are made. They reduce pollution and save energy. Tires now use materials like recycled rubber and natural oils. This helps protect the planet.

- Recycled rubber lowers waste

- Natural oils replace harmful chemicals

- Bio-based materials support sustainability

Smart Tires

Smart tires use technology to improve safety. Sensors in the tires track pressure and wear. They send this data to drivers. This helps prevent accidents and saves money on repairs.

- Sensors monitor tire conditions

- Data helps with maintenance

- Alerts improve driving safety

Advancements In Radial Designs

Radial designs make tires more efficient. They improve fuel economy and handling. New designs focus on better grip and longer life. This benefits both drivers and the environment.

Better radial designs mean smoother rides and less tire wear. This technology continues to grow, offering more benefits each year.

Frequently Asked Questions

What Is Radial Ply Construction In Tires?

Radial ply construction features tire cords arranged at 90 degrees to the tread. This design enhances flexibility and road contact, improving ride comfort and fuel efficiency.

How Does Radial Ply Differ From Bias Ply Tires?

Radial ply tires have cords perpendicular to the tread, while bias ply tires have cords at an angle. Radials offer better durability, traction, and fuel economy compared to bias ply tires.

What Are The Benefits Of Radial Ply Construction?

Radial ply tires provide improved stability, longer tread life, and better fuel efficiency. They also deliver superior handling and reduced heat buildup during driving.

Where Are Radial Ply Tires Commonly Used?

Radial ply tires are widely used in passenger cars, trucks, and SUVs. Their design suits most road conditions and offers enhanced performance and safety.

Conclusion

Radial ply construction offers strong, flexible tire design. It improves tire grip and ride comfort. The layers run across the tire, reducing heat build-up. This type helps tires last longer and perform better. Many vehicles use radial tires for safety and efficiency.

Choosing the right tire helps your car drive smoothly. Understanding radial ply can guide better tire choices. It’s a simple way to boost your driving experience.