Is your tubeless tire losing air, and you’re not sure why? A leaking tire valve might be the hidden culprit.

If you don’t fix it quickly, your tire could go flat at the worst time. But don’t worry—you can repair that valve yourself without spending a fortune or needing special tools. You’ll learn simple, step-by-step tips to stop the leak and keep your tire sealed tight.

Ready to save time and avoid costly repairs? Let’s get started!

Credit: www.youtube.com

Identifying Valve Leak Signs

Leaking tubeless tire valves cause air loss and reduce tire performance. Finding valve leaks early helps keep your tire safe and working well.

Look for signs that show your valve might be leaking. These signs help you know when to check and fix the valve.

Common Leak Symptoms

You can notice a valve leak from how your tire behaves. These symptoms tell you if air escapes from the valve area.

- The tire loses air pressure faster than normal.

- You hear a hissing sound near the valve.

- The tire feels soft or flat without a puncture.

- Moisture or bubbles appear around the valve when wet.

- Valve core feels loose or damaged to touch.

Tools To Detect Leaks

Use simple tools to find valve leaks easily. These tools help you see or hear escaping air.

- Soapy water solution: Spray or apply around the valve. Bubbles show air leaks.

- Pressure gauge: Check if tire pressure drops quickly over time.

- Listening device: A small stethoscope can help hear hissing air.

- Valve core tool: Remove and inspect the valve core for damage.

Preparing For Valve Repair

Fixing a leaking tubeless tire valve needs some planning. It is important to prepare well before starting the repair.

This guide will help you gather tools and follow safety steps to repair the valve correctly.

Gathering Necessary Tools

You will need specific tools to fix the valve leak. Having the right tools ready will make the process easier and faster.

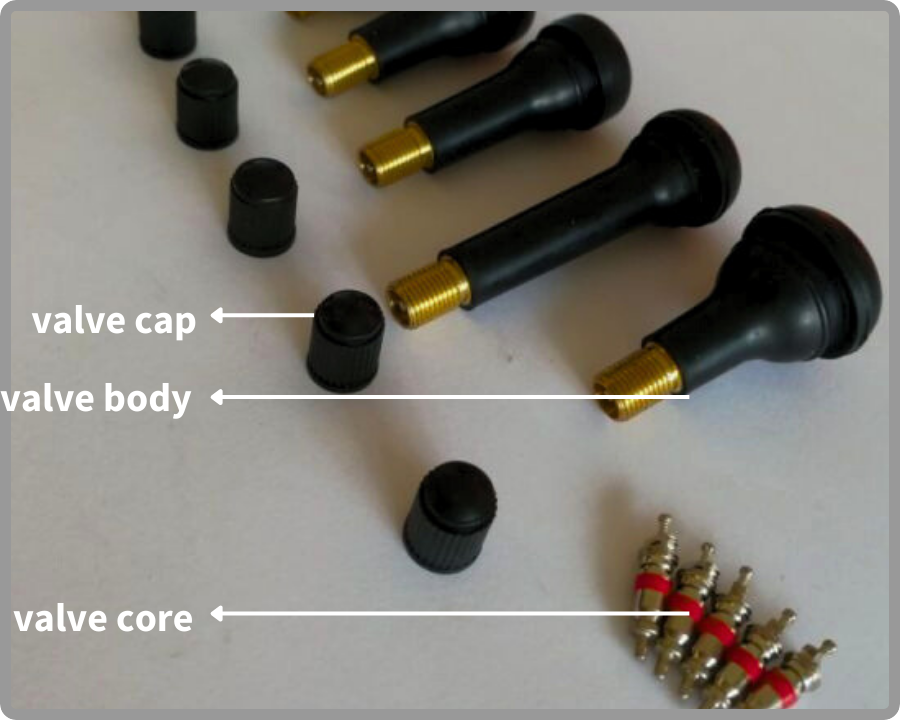

- Tire valve core remover

- Valve stem puller

- Soap and water solution

- Clean rag or cloth

- Air compressor or hand pump

- Sealant for tubeless tires

- Protective gloves

Safety Precautions

Safety is very important while repairing a tire valve. Follow these rules to avoid accidents and injuries.

| Safety Tip | Reason |

| Wear protective gloves | Protect hands from sharp parts and chemicals |

| Work in a well-lit area | See clearly and avoid mistakes |

| Release air pressure slowly | Prevent sudden bursts that can cause harm |

| Keep tools organized | Reduce risk of losing parts or injury |

| Do not rush the repair | Ensure careful work and safety |

Fixing A Loose Valve Core

A leaking tubeless tire valve can cause air loss. One common cause is a loose valve core. Tightening the core can stop the leak quickly.

This guide shows simple steps to fix a loose valve core safely and effectively.

Removing The Valve Cap

First, take off the valve cap by turning it counterclockwise. Keep the cap in a safe place to avoid losing it.

Removing the cap lets you access the valve core easily for tightening.

Tightening The Core

Use a valve core tool or a small wrench to tighten the valve core. Turn it clockwise gently. Do not overtighten to avoid damage.

Check if the leak stops by applying soapy water around the valve. If bubbles appear, tighten a little more.

- Place the tool on the valve core

- Turn clockwise to tighten

- Test for leaks with soapy water

- Tighten more if bubbles appear

- Replace valve cap after fixing

Replacing The Valve Core

A leaking tubeless tire valve can cause air loss and reduce tire performance. Replacing the valve core is a simple fix to stop leaks. This guide shows you how to do it safely and quickly.

Make sure you have the right tools and a new valve core before you begin. Follow the steps below to remove the old core and install the new one.

Removing The Old Core

First, let the tire lose air completely to avoid accidents. Use a valve core remover tool to unscrew the old core carefully. This tool fits inside the valve stem and helps turn the core out.

- Press the valve stem to release any remaining air.

- Insert the valve core remover tool into the stem.

- Turn the tool counterclockwise to unscrew the core.

- Pull out the old valve core gently.

- Check the valve stem for dirt or damage before installing the new core.

Installing A New Core

Take the new valve core and place it inside the valve stem. Use the valve core remover tool to screw it in. Make sure it is tight but do not over-tighten as it can damage the core or valve stem.

| Action | Details |

|---|---|

| Insert New Core | Place the core straight into the valve stem. |

| Tighten Core | Turn the core clockwise using the remover tool. |

| Check Fit | Ensure the core is snug but not too tight. |

| Inflate Tire | Refill air and check for leaks around the valve. |

Sealing Valve Stem Leaks

Leaking tubeless tire valves cause air loss and poor tire performance. Sealing these leaks is easy with the right steps.

Focus on cleaning the valve stem and applying sealant to fix leaks and keep your tire airtight.

Cleaning The Valve Stem

Start by removing the valve cap and core carefully. Dirt and debris often cause leaks around the valve.

Use a clean cloth or brush to wipe the valve stem and inside the valve hole. Make sure the surface is dry before sealing.

- Remove valve core with a valve tool

- Wipe valve stem with a clean cloth

- Brush inside valve hole gently

- Dry the area thoroughly

Applying Sealant

Insert sealant into the tire through the valve stem. Sealant helps block leaks around the valve base and core.

Reinstall the valve core and tighten it. Spin the wheel to spread the sealant evenly inside the tire.

- Use recommended tubeless sealant

- Pour sealant slowly into the valve stem

- Tighten valve core securely

- Rotate tire to spread sealant

Checking For Rim And Stem Damage

Leaking tubeless tire valves can cause problems. It’s important to check for rim and stem damage. This ensures your tire stays airtight.

Regular inspections can prevent bigger issues. Focus on the rim hole and valve stem condition.

Inspecting The Rim Hole

The rim hole must be smooth and free of debris. Any rough edges can lead to leaks.

Use a clean cloth to wipe the rim hole. Check for any cracks or sharp areas.

- Look for dirt or debris around the hole

- Feel for any rough edges or cracks

- Ensure the surface is smooth

Assessing Valve Stem Condition

The valve stem should be in good shape. A damaged stem can cause air leaks.

Check for cracks or splits in the valve stem. Gently wiggle it to test its stability.

- Look for visible cracks or splits

- Ensure the stem is securely attached

- Test for any wobbling or looseness

Reinflating And Testing The Tire

A leaking tubeless tire valve can cause problems. Reinflating and testing the tire is essential for safety.

Follow these steps to ensure your tire is properly inflated and leak-free. This guide will help you understand the process better.

Proper Inflation Pressure

Maintaining the right pressure in your tire is crucial. It prevents wear and ensures a smooth ride.

- Use a reliable pressure gauge.

- Inflate the tire to the recommended PSI.

- Recheck the pressure after a few minutes.

Leak Testing Methods

After inflating, it’s important to check for leaks. This ensures the tire will hold air properly.

- Apply soapy water around the valve.

- Look for bubbles indicating a leak.

- Use a spray bottle for even coverage.

| Method | Tools Needed |

| Soapy Water | Spray bottle, dish soap |

| Visual Inspection | Flashlight |

| Pressure Check | Pressure gauge |

Credit: www.reddit.com

Preventing Future Valve Leaks

Leaking tubeless tire valves can cause flat tires and unsafe rides. Preventing leaks helps keep your tires in good shape. Simple steps can stop leaks before they start.

Check your valve regularly and use good parts. This keeps air inside and avoids costly repairs.

Regular Maintenance Tips

Clean the valve stem often to remove dirt and dust. Dirt can stop the valve from sealing well. Use a soft cloth or brush to keep it clean.

Check the valve core tightness. A loose core can cause leaks. Use a valve core tool to tighten it gently. Avoid over-tightening, which can damage the valve.

- Clean valve stem weekly

- Inspect valve core for tightness

- Replace worn valve caps

- Check for cracks or damage

Choosing Quality Valve Components

Use valve stems made from strong materials like brass or aluminum. These last longer and resist damage better than plastic. Good quality parts reduce the chance of leaks.

Choose valve cores with a reliable seal design. Some cores have rubber gaskets for better air tightness. Always replace valve caps to protect the core from dirt and moisture.

- Select valve stems with metal construction

- Pick valve cores with rubber seals

- Buy valve caps that fit snugly

- Avoid cheap, low-quality parts

Credit: tireonway.com

Frequently Asked Questions

How Do I Fix A Leaking Tubeless Tire Valve?

First, deflate the tire and remove the valve core. Inspect the valve for damage or dirt. Clean or replace the valve core if needed. Reinstall and inflate the tire to check for leaks. Use soapy water to spot escaping air bubbles.

What Tools Are Needed To Repair Tubeless Valve Leaks?

You need a valve core remover, soapy water spray, and a replacement valve core or sealant. A tire inflator or air compressor is helpful. These tools help you detect leaks and replace faulty valve parts safely and efficiently.

Can Sealant Fix A Leaking Tubeless Tire Valve?

Yes, tubeless tire sealant can temporarily seal small leaks around the valve. However, if the valve is damaged or corroded, replace it for a long-term fix. Sealant works best with minor leaks or punctures near the valve stem.

How Often Should Tubeless Tire Valves Be Checked?

Check tubeless tire valves every 3 to 6 months or before long rides. Regular inspections help catch leaks early and maintain proper tire pressure. This prevents sudden deflation and improves tire performance and safety.

Conclusion

Fixing a leaking tubeless tire valve saves time and money. Follow the steps carefully for best results. Check the valve regularly to avoid future leaks. Use proper tools and replace parts when needed. A small leak can cause big problems on the road.

Keep your tires safe and maintain good air pressure. Practice these tips to enjoy a smooth, safe ride. Simple care makes a big difference in tire performance. Stay alert and fix leaks as soon as you find them. Your bike or vehicle will thank you.