Are you tired of guessing how tight your bolts really are? Using a torque angle gauge can change the way you work, making your projects safer and more reliable.

This simple tool helps you achieve precise torque by measuring the exact angle you turn a bolt after applying initial torque. If you want to avoid costly mistakes and ensure everything is tightened perfectly, understanding how to use a torque angle gauge is a game-changer.

Keep reading, and you’ll learn easy steps to master this tool and get professional results every time.

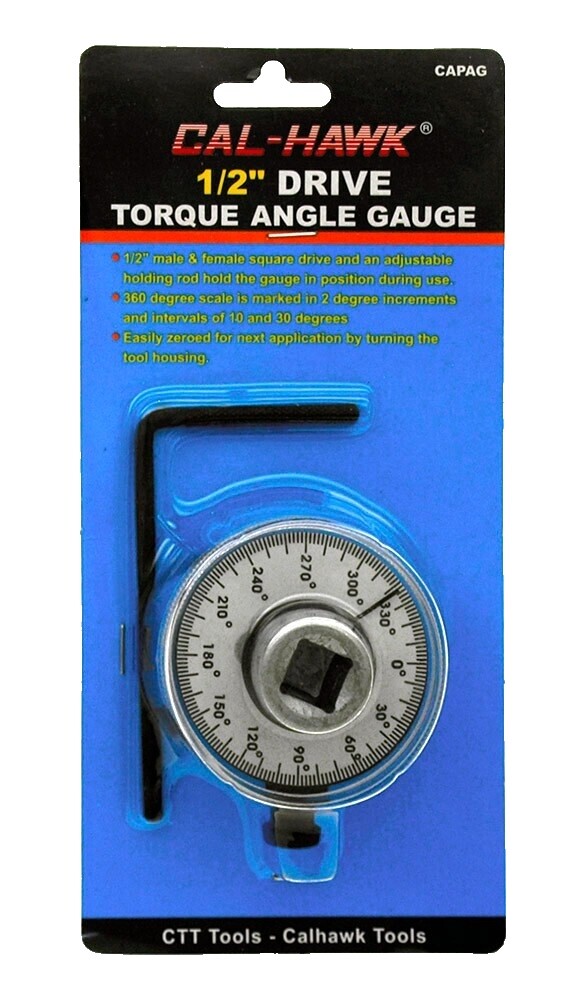

Credit: wilmarllc.com

Torque Angle Gauge Basics

A torque angle gauge measures how far a bolt turns after reaching a specific torque. It helps ensure the bolt tightens correctly. This tool is useful for precise assembly tasks.

Using a torque angle gauge improves joint strength and safety. It reduces risks caused by over or under-tightening bolts.

Purpose And Benefits

The main purpose of a torque angle gauge is to measure the rotation angle of a bolt. This helps confirm the bolt is tightened to the right stretch level.

Benefits include better joint accuracy and longer bolt life. It also lowers chances of bolt failure by controlling tightness.

- Ensures precise bolt tension

- Improves safety in mechanical joints

- Prevents damage from over-tightening

- Supports quality control in assembly

Types Of Torque Angle Gauges

There are different types of torque angle gauges. Some are simple mechanical dials, while others use digital displays.

Mechanical gauges are easy to use and durable. Digital ones give more precise readings and may have memory functions.

- Mechanical torque angle gauges

- Digital torque angle gauges

- Combination tools with torque and angle functions

Key Components

A torque angle gauge has key parts that help measure bolt rotation. These parts work together to give accurate readings.

| Component | Function |

|---|---|

| Dial or Display | Shows the angle measurement |

| Pointer or Needle | Indicates the exact angle on the dial |

| Attachment Mechanism | Connects the gauge to the wrench or bolt |

| Calibration Scale | Ensures accuracy of readings |

Credit: www.amazon.ca

Preparing For Torque Angle Measurement

Using a torque angle gauge helps tighten bolts correctly. Preparing the tool and work area is important. This ensures accurate and safe measurements.

Before starting, you need to select the right gauge, calibrate it, and follow safety rules. These steps make the process smooth and reliable.

Selecting The Right Gauge

Choose a torque angle gauge that fits your bolt size and torque range. Different gauges work for different jobs. Pick one that matches your tool and fastener.

Check the gauge’s specifications and make sure it is compatible with your torque wrench. Using the wrong gauge can cause errors or damage.

Calibrating The Tool

Calibration makes sure the torque angle gauge reads accurately. Do this before every use or after long storage. Follow the manufacturer’s instructions carefully.

- Set the gauge to zero before starting

- Use a known angle to check accuracy

- Adjust if the reading is off

- Keep a calibration log for reference

Safety Precautions

Wear safety glasses and gloves to protect yourself. Make sure the work area is clean and free of hazards. Avoid distractions while measuring torque angles.

Do not force the gauge or wrench beyond their limits. Handle tools carefully to avoid injury or damage. Follow all safety guidelines for your equipment.

Step-by-step Usage Guide

Using a torque angle gauge helps ensure fasteners are tightened correctly. This guide explains how to use it safely and accurately.

Follow these steps to set up the gauge, measure the torque angle, and record your results.

Setting Initial Torque

Start by tightening the bolt to the manufacturer’s recommended initial torque. Use a torque wrench for this step.

Make sure the torque wrench is calibrated for accurate readings.

Attaching The Gauge

Attach the torque angle gauge to the torque wrench. Ensure it fits securely and aligns with the wrench scale.

- Place the gauge on the wrench handle

- Lock it in place with the mounting clip

- Check that the dial or digital display is visible

- Zero the gauge before use

Measuring The Torque Angle

Turn the bolt slowly while watching the gauge. The gauge shows how many degrees the bolt turns after the initial torque.

| Action | Details |

| Start Turning | Apply steady force on the wrench |

| Watch Gauge | Note the angle increase on the display |

| Stop at Target | Stop when the desired angle is reached |

Recording Results

Write down the torque angle and initial torque for each fastener. Keep a log for quality control and future reference.

Use a table or digital sheet to track your measurements clearly.

Common Applications

A torque angle gauge helps measure the angle of rotation when tightening bolts. It ensures bolts are tightened to exact specifications.

This tool is useful in many fields where precise torque is critical. Below are common applications for using a torque angle gauge.

Automotive Repairs

In automotive repairs, a torque angle gauge helps tighten engine bolts and other fasteners. Proper torque prevents damage and ensures safety.

- Engine cylinder head bolts

- Wheel lug nuts

- Suspension components

- Transmission bolts

Machinery Assembly

Machinery assembly requires accurate bolt tension to keep machines working well. A torque angle gauge helps meet these exact needs.

| Component | Torque Angle Use |

| Gearbox bolts | Ensures tight fit without stripping threads |

| Bearings | Prevents over-tightening that causes damage |

| Frame assembly | Keeps structural integrity |

Aerospace Maintenance

Aerospace parts need precise torque to keep aircraft safe. A torque angle gauge measures bolt rotation to meet strict standards.

Common aerospace uses:

- Fastening engine components

- Securing landing gear parts

- Tightening airframe connections

Troubleshooting Tips

Using a torque angle gauge can sometimes be tricky. It’s important to know how to troubleshoot common issues. This guide will help you fix problems and use the tool effectively.

We will discuss inaccurate readings, gauge malfunctions, and handling difficult fasteners. These tips will make your tasks easier and more accurate.

Inaccurate Readings

Inaccurate readings can happen if the gauge is not calibrated. Check the calibration regularly to ensure accuracy. Always reset the gauge before starting a new task.

Make sure the gauge is properly aligned with the fastener. Misalignment can lead to errors. Hold the gauge steady while using it.

- Check calibration before use

- Reset gauge for each task

- Align gauge with fastener

- Hold gauge steady

Gauge Malfunctions

Gauge malfunctions can cause delays. If the gauge does not turn on, check the battery. Replace it if necessary. Ensure all parts are clean and free from debris.

If the gauge is still not working, consult the manual. It may have specific troubleshooting steps. Contact customer support for further assistance.

- Check and replace battery

- Clean all parts

- Consult the manual

- Contact customer support

Handling Difficult Fasteners

Some fasteners are hard to handle. Use the correct size and type of wrench. This ensures a good grip and prevents slipping.

Apply steady pressure when using the gauge. Sudden movements can lead to mistakes. Practice makes perfect, so keep trying until you get it right.

- Use correct wrench size and type

- Ensure good grip on fastener

- Apply steady pressure

- Practice for better handling

Maintaining Your Torque Angle Gauge

Taking care of your torque angle gauge helps it last longer. Proper maintenance keeps it accurate and reliable.

Regular upkeep includes cleaning, correct storage, and calibration checks. These steps protect your tool and ensure precise measurements.

Cleaning Procedures

Clean your torque angle gauge after each use. Remove dirt and oil to prevent damage and wear.

- Use a soft cloth to wipe the surface gently.

- Avoid harsh chemicals or water that can harm internal parts.

- Apply a small amount of lubricant on moving parts if needed.

- Check for any debris in the gauge’s moving mechanism.

Storage Recommendations

Store your gauge in a dry, clean place to avoid rust and damage. Keep it away from extreme temperatures and humidity.

| Storage Tip | Reason |

| Use a protective case | Prevents dust and physical damage |

| Keep in a cool environment | Avoids heat-related tool distortion |

| Place away from moisture | Stops rust and corrosion |

| Store flat or hanging | Maintains tool shape and function |

Regular Calibration

Calibration ensures your gauge measures angles accurately. Check calibration often based on usage frequency.

- Test the gauge against a known standard or reference tool.

- Send the gauge to a professional calibration service yearly.

- Record calibration dates and results for future reference.

- Recalibrate if the gauge suffers a drop or heavy impact.

Credit: www.420spotshop.com

Frequently Asked Questions

What Is A Torque Angle Gauge Used For?

A torque angle gauge measures the rotational angle of a fastener. It ensures precise tightening beyond standard torque values. This tool helps avoid over or under-tightening critical bolts. It is commonly used in automotive and mechanical applications for accuracy.

How Do You Read A Torque Angle Gauge?

To read a torque angle gauge, align the zero mark with the pointer. Tighten the fastener and watch the gauge’s dial rotate. The angle shown indicates how far the fastener has turned past the initial torque. Stop tightening when the desired angle is reached.

Can A Torque Angle Gauge Improve Bolt Tightening Accuracy?

Yes, a torque angle gauge enhances tightening precision. It measures the exact rotation angle after reaching torque specs. This prevents bolt damage and ensures proper clamping force. Using this gauge leads to consistent and reliable assembly results.

When Should You Use A Torque Angle Gauge?

Use a torque angle gauge when specs require angle-tightening after torque. It is crucial for critical fasteners in engines, suspension, and structural components. This method ensures correct bolt tension and avoids loosening or failure during operation.

Conclusion

Using a torque angle gauge helps you tighten bolts precisely and safely. It ensures the right angle, avoiding damage or loose parts. This tool makes your work more accurate and reliable. Practice using it step by step for best results.

Keep the gauge clean and check it often. Simple care keeps it working well for a long time. Remember, careful use improves your projects and saves time. Try it on your next task to see the difference.